Facility

State-of-the-art facility, channeled by technology and precision, controls every stage of denim garment manufacturing, ensuring quick turnarounds for our customers worldwide.

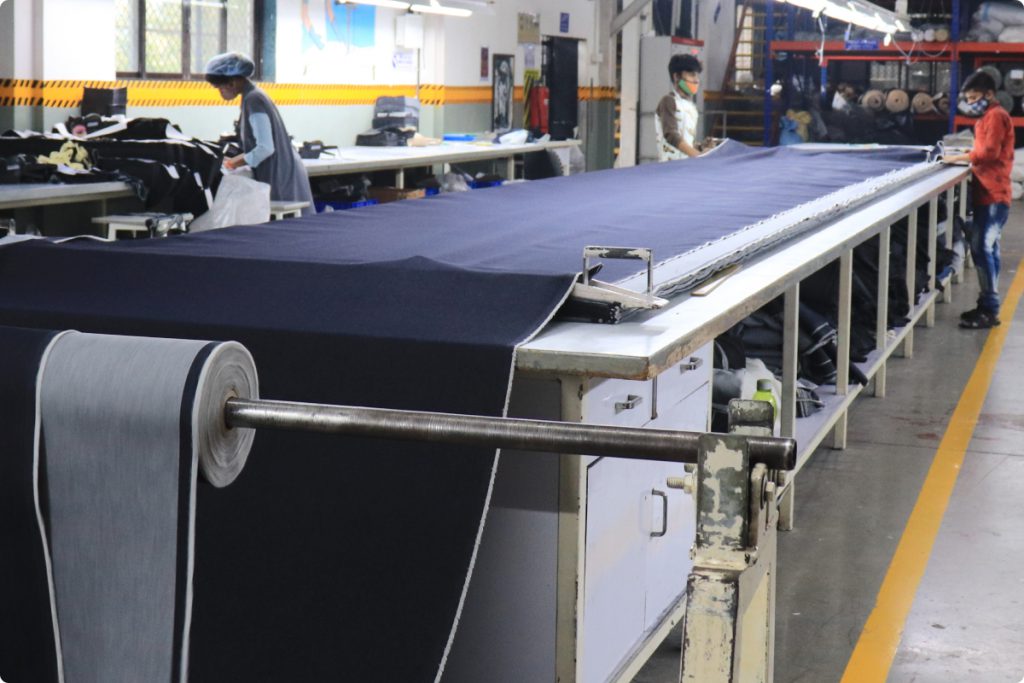

CAD and Cutting

Equipped with Rich Peace CAD systems for pattern and fit exaction that ensures low and adequate fabric consumption.

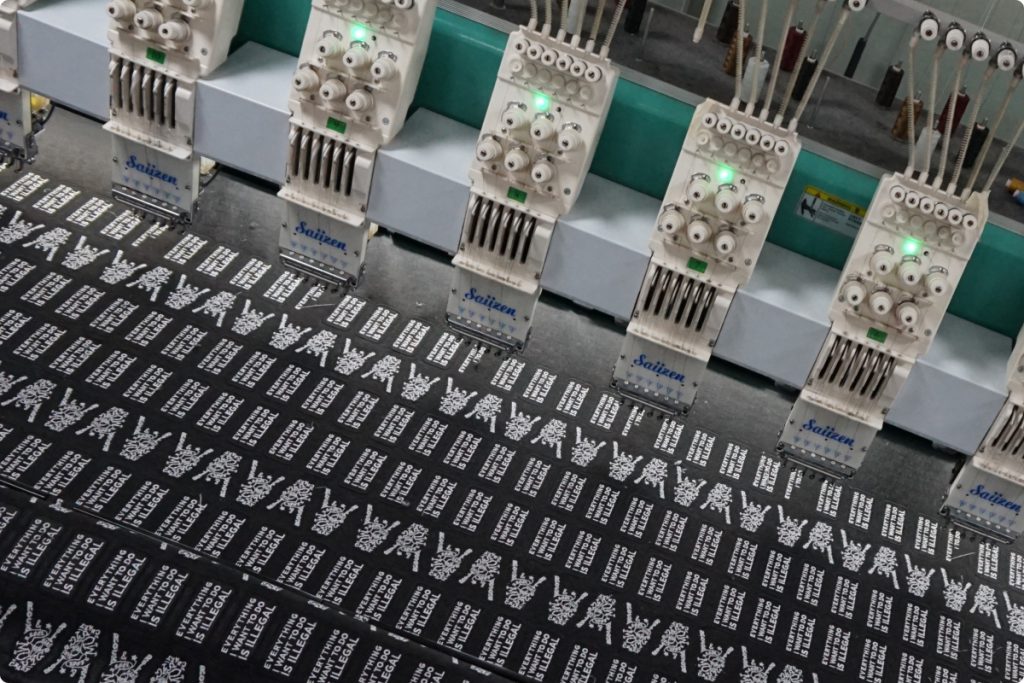

Embroidery

Computerized machines with multi pattern capacity applicable for panel as well as ready garments. Up to 12 heads x 6 colors for high efficiency and colors in bulk production and single heads x 9 colors for sampling.

Stitching

The German, Italian and Japanese technology partners spur on our stitching expertise and help us deliver exquisite craftmanship yielding superior results to our clients.

Handwork

Traditional handwork process for manual hand sanding, whiskers, grinding, tearing, mending, 3-D creasing etc.

Laser

Advanced and eco-efficient laser technology for authentic garment finishing by Jeanologia. An invention that promotes sustainability towards planet and people, capable of giving you the ‘aged look’ on a denim!

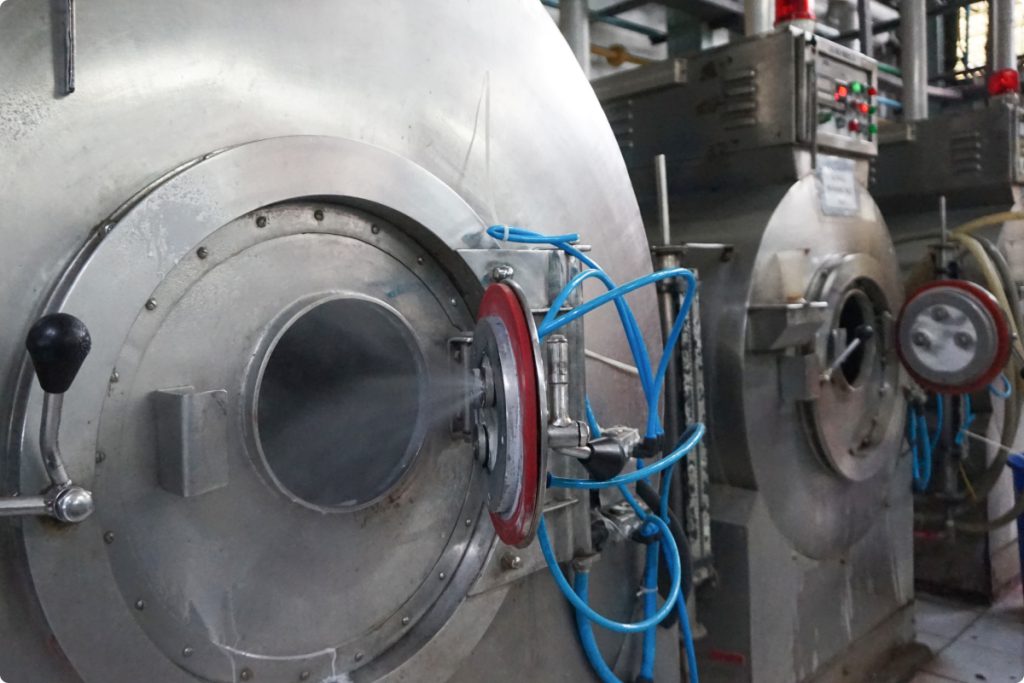

Washing

Complete front load machines with an MLR of 1:3, by TOLKAR. We have included sustainable processes from Turkey and Italy like Smart form technology, Nano-bubble technology and Ozone wash.

Printing

Six screen butterfly machine with curing. Long screen print table for larger panels or full garment print. Inhouse, screen exposing, making & washing facility

Packing

Italian and Japanese Form Finishers installed here to steam and blow the jeans to have the final smooth finish before getting to the customer.

Snap Attacher from Hong Kong seals the Jeans with authentic buttons and rivets.

QAM

TIJF has always believed in quality, and has thorough quality controlling systems & procedures at every step of production. We follow 2.5 AQL system.